Our Craftsmanship Standards is a series of articles that take you behind the scenes at Paperblanks. Quality is the single most important part of the design process of our books. We attend to each detail and apply rigorous quality control checks to every component of our journals.

What Components are Important in Book Craftsmanship?

When detecting quality, we look for evidence of the following elements in book structure and design:

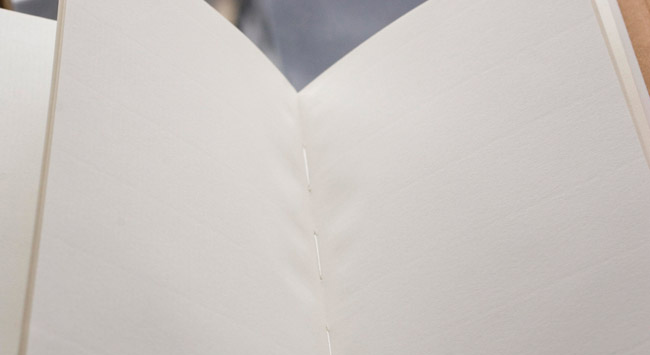

- The binding method (whether it is sewn or not sewn)

- How flat the book opens

- The quality of the paper

- The grain direction of the paper

We have covered the first three topics in previous articles here, here, and here, respectively. Our discussion on grain direction follows.

Grain Direction

With all paper, whether it is produced by hand or by machine, the fibres cross in many different directions. This is what gives paper its strength. Paper made by hand does not have a uniform grain direction, whereas the fibres in paper produced by a machine tend to run in the same direction. This is because in all commercially produced paper, pulp is moved through a machine in a swift, forward-moving direction. This forward movement lines up most of the pulp fibres parallel to the direction they are travelling, creating what is called grain direction.

Grain direction is an essential aspect of producing a well-crafted book. It may seem like a small detail, yet it makes a crucial impact on the long-term lifespan of a book.

Rip a piece of paper and you’ll notice that it tears very easily, and very straight, in one direction, yet quite messily in the other. A similar result occurs if you fold a sheet of paper. In one direction it will fold neatly and easily – not so in the other direction.

The general rule in bookmaking is that grained papers and binding boards should be aligned vertically, with the grain parallel to the spine of the book.

Expanding Across The Grain

Typically, a paper fiber will swell or shrink four to five times more in thickness than in length, and all paper expands across the grain. Placed in environments that are always changing, especially those with higher humidity and moisture, paper fibres will be affected.

When the grain direction runs perpendicular to the spine, one edge of the paper is secured to the bound edge of the bookblock. This means that the paper on this edge is unable to expand, which causes it to buckle and wave on the unbound side only.

When the binding goes against the paper’s grain like this, it puts stress on the fibres. The book will not close easily and the pages will warp over time.

For this reason, the grain direction of the paper must always be parallel to the spine of the book. Keeping the paper oriented this way takes advantage of the paper’s natural strength and minimizes its weaknesses. As you turn the pages, you are going with the grain.

After quality, may I suggest “usability design” for the books be the next most important part of the design process.

For instance, what do you write with in a lined journal?

A pen?

Is there space for a pen in the lined journals that Paperblanks designs?

If not, then how about trimming the pages an additional 1/8″ and leaving space for the most important accessory for a Paperblanks journal.

good info!